About TECHNOGENIA

TECHNOGENIA, THE COMPANY

Technogenia is headquartered in Saint Jorioz France with regional offices and laser cladding facilities in the US, UK, Singapore and Dubai.

As the global leader in hardfacing technology, Technogenia facilities, licensed partners and its network of distributors are strategically located to support our growing list of clients worldwide. To request a brochure or to contact the closest facility please call (405) 470-3350 or (936) 441-4770 - or send an email request to

sales-usa@technogenia.com.

LASERCARB ® DEVELOPMENT

The Lasercarb® process was developed by Technogenia beginning in 1983 and further refined and improved in 2003 by incorporating a high power

diode laser with CNC multi-axis control

that is precise and repeatable for exact placement

of the powder deposit. When combined with application-specific, proprietary Technolase® powders, the Lasercarb® process can be applied to virtually any component profile either on the OD or the ID to protect against abrasion, erosion and corrosive environments.

For over 30 years, Technogenia, the leader in the anti-wear protections, has brought to customers the best quality through the state of the art laser cladding technology. Using its proprietary manufactured spherical cast tungsten carbide combined with the latest laser cladding technology, LaserCarb® brings the best solution for effectively eliminating your wear problems.

- 1979: Creation of Technogenia, in France.

- 1983: Beginning research of ‘Cold Crucible’ Tungsten Carbide fusion with electromagnetic levitation.

- 1986: Implementation of the ‘Cold crucible’ system of Tungsten Carbide fusion by induction.

- 1987-1988: Launch of Technosphere® and Technocasting® process.

- 1990: Beginning research on Carbide deposition using high power laser.

- 1992: Introduction of LaserCarb®

- 1993: Installation of a 5 KW CO2 laser, start up of the industrial phase.

- 2000: Research on Diode Laser.

- 2003: Technogenia introduced LASER CLADDING TECHNOLOGY, in Great Britain, with the implementation of a new high power diode laser.

- 2005-2006: Implementation of the diode technology at Technogenia S.A in France.

- 2008: Opening of the first US laser cladding facility in Conroe, TX

- 2009: Introduction of LaserCarb® ID an internal Laser cladding process

- 2011: Second US facility opened in Oklahoma City, OK

- 2017: Technogenia Middle East facility opened

CAPABILITIES

- OD and ID cladding

- Multiple high powered laser systems ranging from 2KW-7KW

- 5 Axis and 7 Axis machines with CNC programmable controllers

- Grinding equipment for OD and ID applications

- Temperature controlled oven

- Stamping

- LPT Testing

- Laser Heat Treating

QUALITY STANDARDS

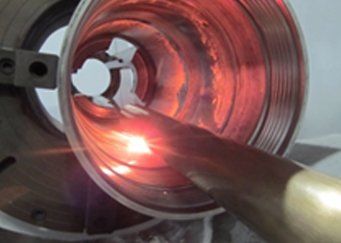

VIDEO

See the Lasercarb process in action!